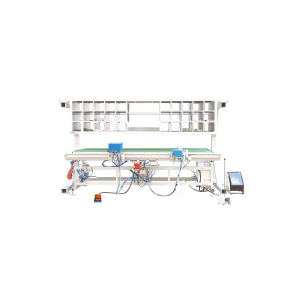

Double Head CNC Corner Cleaner WDJ2A-CNC-120

Double Head CNC Corner Cleaner WDJ2A-CNC-120

Characteristic

1.The cleaning of the two corners of the rectangular frame (fan) is completed at one time, which has high efficiency and meets the needs of mass production

2.It can be used to clean all kinds of profile welding corner facade, upper and lower plane welds and adhesive groove welds

3.Unique super head structure design ensures long-term accuracy and stability

4.High speed motor is used to clean the seam of adhesive strip groove, with high precision and appearance quality

5.It can realize dimension error compensation with high precision

6.The unique internal positioning mode ensures the accurate positioning of welding workpiece

7.CNC positioning of window size, high precision, easy operation

8.Servo drive system, numerical control system, solenoid valve, triplet and other main components are imported famous brand products with reliable performance and long service life

9.It can store the processing program of many kinds of profile

10.It can realize the arc difference compensation and diagonal difference compensation, and can ideally meet the needs of making high-quality doors and windows with various section profiles

11.The height design conforms to the principle of ergonomics and is easy to operate

Main technical parameters

| Power supply | 380V, 50 Hz |

| Saw blade milling cutter motor speed | 18000r / min |

| Saw blade milling cutter motor power | 0.55kw × 2 |

| Total power | 7.5kw |

| The gas pressure is | 0.5 ~ 0.8MPa |

| Gas consumption | 60L / min |

| Processing profile height | 30 ~ 120mm |

| Processing window frame range | 500 ~ 3000mm (moving direction of movable head) |

| The overall dimension of the equipment is | 5250mm × 3150mm × 1950mm |

| It weighs about | 2500kg |